|

| February 13, 2018 | Volume 14 Issue 06 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Army lab's laser forming technique may prove useful as new way to bend metal

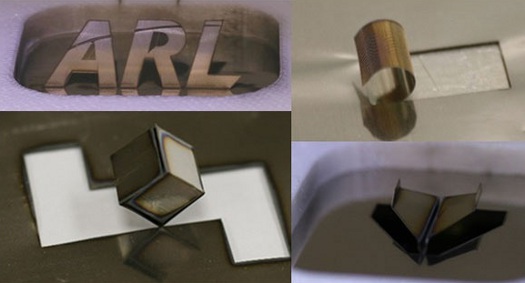

The ARL logo, folded and positioned without human intervention, via a laser cutter. With further development, this technique could allow complete assemblies to be built directly in the laser cutter itself, which could bring an important new functionality to a widely available tool. [U.S. Army Photo by Jhi Scott]

By Jenna Brady, ARL

What do the ancient Japanese art of origami and laser cutting have in common? For the U.S. Army, it could mean the saving of Soldiers' lives on the battlefield.

Researchers Dr. Nathan Lazarus and Gabriel Smith at the U.S. Army Research Laboratory have demonstrated for the first time the creation of complex 3D parts directly from a blank sheet of metal using only a laser cutter.

Laser cutters are typically designed to cut 2D parts from a single 2D sheet of material using a focused light source that heats metal so that the material leaves the surface.

Instead of using this classic technique, Lazarus and Smith set the laser to a lower power level, causing controlled heating instead of cutting.

The heating causes relative expansion, which in turns allows the metal to be bent in a process called laser forming. With laser forming, the direction in which the metal bends (i.e. up or down) can be controlled with power and beam speed, which is a powerful aspect that cannot be achieved with the traditional approach.

This process is all hands-free, low-cost, efficient, and compatible with fabricating thousands of parts at a time.

To create these parts, instead of using a classic technique, Lazarus and Smith set the laser to a lower power level, causing controlled heating instead of cutting. The heating causes relative expansion, which in turns allows the metal to be bent in a process called laser forming. [U.S. Army Photo]

"One of the most vulnerable aspects of our Army is its logistical tail, the supply convoys that keep our troops in the field," Lazarus said. "Being able to rapidly produce replacement parts and systems without having to bring them in from elsewhere is therefore a critical need in today's Army, driving a variety of programs at ARL through the Manufacturing at the Point of Need Essential Research Area."

According to Lazarus and Smith, this research, aimed at making parts with a 3D component using a low-cost, typically 2D, widely available machine tool, is a potential game changer in rapidly making parts at forward bases and deployments throughout the world.

Initial demonstrations of laser forming origami have included a wide range of possible parts from cubes and coils to arcs and cylinders. Materials that can be laser formed include metal, glass, and crystalline semiconductors.

"Our current version that involves thin metal and lower power could easily create a new antenna for a radio, a new inductor for a power system, new heat sinks for cooling, and much more," Lazarus said. "With a higher power laser, which we've been in talks to try, it would be possible for example to build a replacement armor plate for a tank, sloped and curved appropriately, or a helmet."

According to Lazarus, this is a general manufacturing technique that could be easily adapted to many metal parts or components.

"There is no doubt that Soldiers make great use of many, many such parts in their vehicles, their electronics, their heating and cooling units, and so forth," Lazarus said.

Lazarus and Smith have explored using this same approach to fold and position multiple parts without human intervention, as seen in the ARL logo video.

With further development, this technique could allow complete assemblies to be built directly in the laser cutter itself, which brings an important new functionality to a widely available tool.

"This is a general advance for a widely available laser machining technology, which complements the revolution in computer-controlled additive manufacturing," Smith said. "We have a number of on-going projects building on our initial work. These range from investigating scaling up in power and build volume to looking at building a variety of useful devices. We have had interest from both within and outside of ARL to extend this work."

Researchers Dr. Nathan Lazarus (left) and Gabriel Smith (right) at the U.S. Army Research Laboratory have demonstrated for the first time the creation of complex 3D parts directly from a blank sheet of metal using only a laser cutter. [U.S. Army Photo by Jhi Scott]

Folding 2D materials to create 3D shapes is widely used in applications ranging from balloon stents in hearts to solar panel arrays on the International Space Station.

However, according to Lazarus and Smith, there are only a few limited examples of creating folded structures using laser forming, and their research has pushed far beyond what has been done previously.

"Without ever having to touch the workpiece, we went from a blank, unpatterned sheet of metal to a complex 3D part, including up and down folds, all with the laser itself," Lazarus said. "This combination of etching, cutting, and two types of folding, one mechanism for folding up and another for folding down, was the primary innovation of our work."

In addition to being a benefit for the Army and Soldiers, this technique has applications in developing countries, where needed resources are not readily available.

"Right now, it's often very, very difficult to obtain modern technology in rural areas such as the developing regions of Africa, for instance," Lazarus said. "Low-cost systems like 3D printers and laser cutters are far more readily plausible to install in a remote village to allow the people there to rapidly build tools and other items than a modern factory, and provide far more capability than, say, a village blacksmith or toolmaker. And without too much imagination, it is possible to see these same people beginning to produce extra parts for export to neighboring villages or the rest of the world, allowing better economic development and improved conditions with time."

As for the future, Lazarus and Smith feel that they are far from exhausting the capabilities of their process, a process that could forever change the safety and capabilities of Soldiers in combat and the quality of life of individuals living in developing countries.

Source: U.S. Army Research Laboratory

Published February 2018

Rate this article

View our terms of use and privacy policy